When you need to lift, push or support a heavy load in tight industrial spaces, it can be hard to find the right solution. Even if you find a jack that meets some of your requirements, the manufacturer may not offer the options you need to comprise a complete unit at an acceptable cost. A rack and pinion jack can provide the right combination of load handling, torque and versatility in a compact unit. That’s why it pays to work with a rack and pinion jack manufacturer that is known for its quality gearing components and technical expertise.

At Redex, our Rack Jack products transform rotary motion to linear motion and vice versa while combining heavy-duty performance with simplicity and value. Here’s how our Rack Jack products work:

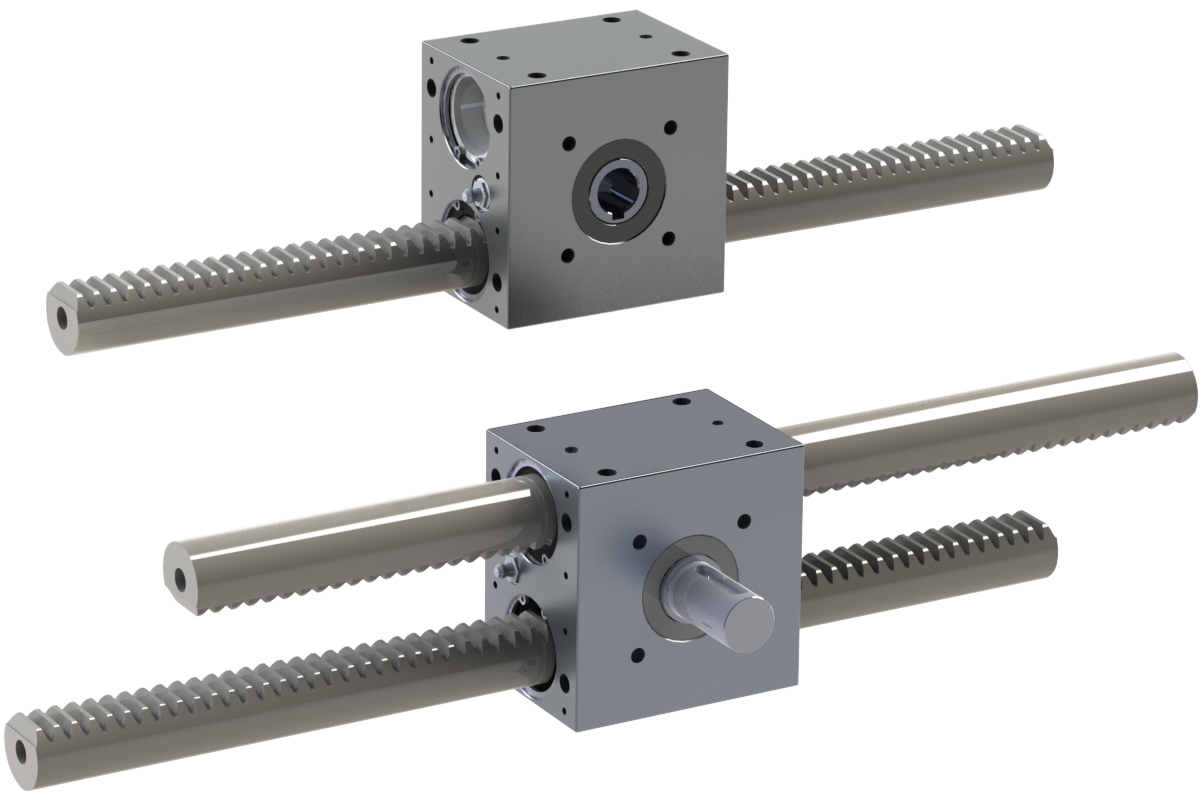

The assembly consists of a hollow-bore pinion and one or two racks – depending on the application – which create a force-locked connection inside a robust, square housing. As the pinion is driven by the motor, the racks move linearly in opposite directions. Unlike an electronic approach that typically involves two motors that require programming and significant time and effort, Redex Rack Jacks need just a single motor to deliver mechanically synchronized linear motion as part of a central, easy-to-implement system.

This method, along with our quality, durable gearing materials, allows us to deliver greater load capacity and torque in a compact space. And, our standardized components keep costs in line. Six sizes are available, offering lifting forces from 800 to 160,000 Newton (180 to ~36,000 pounds) lifting force.

Additional features include:

- High bending stiffness thanks to the rack’s large diameter and wide teeth.

- Robust design for long service life with continuous use.

- Precise positioning and high repeatability.

- Four standard input options.

- Rack lengths up to 110 inches (2,800 millimeters).

There’s a Rack Jack for Your Lifting and Pushing Needs

We offer Rack Jacks with one or two racks. In the double version, the racks move in opposite directions in order to push two loads the same distance at the same time. Rack Jack is well-suited for applications involving tool positioning, centralizing, actuating of doors or lifting frames of all kinds, gripper movement, sequential width adjustments, lifting columns for conveyors and systems and angular adjustment on pivoting devices, just to name a few.

As a leader and expert in quality gearing products, we have both the capability and economy of scale to cost-effectively customize a Rack Jack. For applications requiring extra lifting force within limited space, we can create a Rack Jack with double-sided toothing. The rack, with teeth cut on two sides, allows it to transmit up to twice the force of a similar-diameter rack, while at the same time keeping the moving mass of the rack low. Other options include special housings, custom pinion shafts for different connections, customer-specified rack lengths and end machining, as well as integrated gearboxes, bellows and couplings. We can also add a linear guide for applications with side loads.

The Clear Choice for Lifting and Pushing Applications

When you take a look at the benefits that our Rack Jack provides, the choice is clear. Redex Rack Jacks offer an exceptional combination of features, quality and customization options — all in a compact size — to give you the best value and performance among rack and pinion jack products. Our sales engineers can help you select and optimize a Rack Jack that best fits your needs.

For more information about Rack Jack, visit our product page.